Airless nozzles are a commonly used type of nozzle in spray equipment. They atomize paint directly under high pressure, instead of using compressed air. The design and working principle of airless nozzles give them significant advantages over other types of nozzles in some applications.

Working Principle

High-Pressure Atomization

Airless nozzles pressurize the paint to extremely high levels (usually 2000-3000 PSI, or even higher) and then eject it through a very small nozzle aperture. The paint rapidly disperses and atomizes as it leaves the nozzle.

Uniform Coating:

The high-pressure atomization process produces very fine paint particles, which help to form a smoother, more uniform coating.

Design Features

The aperture of an airless nozzle is usually small, which helps to produce a finer spray.

Due to the high pressure of the paint passing through the nozzle, it is typically made from highly wear-resistant materials, such as tungsten steel or ceramics.

Spray Painting Techniques

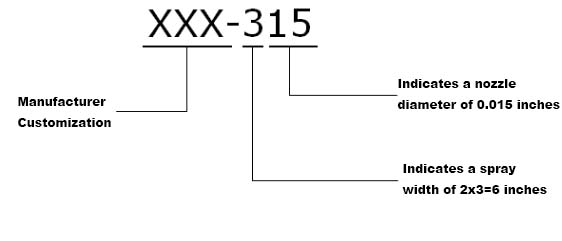

Calibration of Nozzle Models

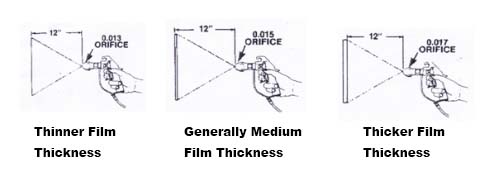

Nozzle Model and Film Thickness

For nozzles with the same spray width but different diameters, the thickness of the film sprayed by the larger diameter nozzle is considered thicker.

For nozzles with the same diameter but different spray widths, the thickness of the film sprayed by the larger diameter nozzle is considered thicker.

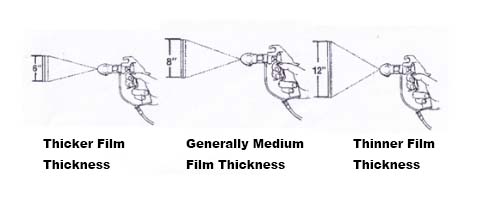

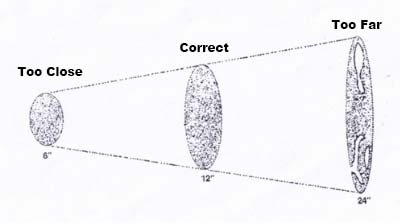

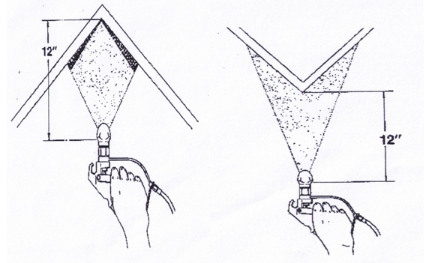

Spray Gun Distance

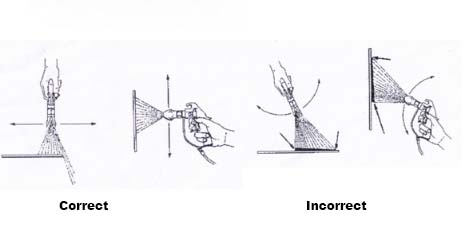

Spray Gun Position

The spray gun should always be kept perpendicular to the object being sprayed.

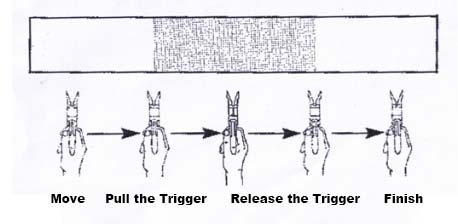

Spray Gun Movement

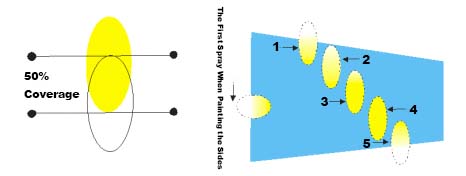

Spray Width Overlap

How to Spray Paint Corners

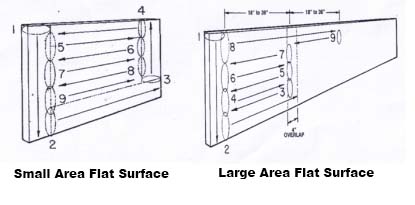

How to Spray Paint Flat Surfaces